Automated analysis of Baffle Bolts

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

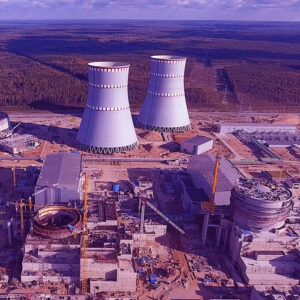

Making Nuclear Energy the Safest Way to Produce Electricity

Inicio | Nuclear Archives | Emergency Management

After the earthquake in Japan on March 11, 2011, European countries decided to conduct a coordinated revaluation of the safety margins in their nuclear plants, taking into consideration the lessons learnt from Fukishima.

This led the Nuclear Safety Council to establish a set of “stress tests” in Spain, which were specific to each Spanish nuclear plant.

Faced with the unlikely event that their refrigeration systems fail; Spanish nuclear plants have now pushed for the creation of an Emergency Support Centre (ESC), complete with the equipment needed to help with the extraction of said residual heat.

This support will be based on generators that can power the plant equipment and pumps that can provide the necessary rate of refrigeration. Tecnatom has been appointed by Spanish nuclear plants to manage the Spanish ESC.

The ESC has a centralised storage system which is located far away from any Spanish nuclear site. It also has a specialised intervention unit which can be implemented and deployed at the requested site within 24 hours, acting as an additional aid to the site’s emergency plan.

The ESC also has a team of on-site technicians at each plant who have a detailed knowledge of the strategies, connections, resources and facilities needed for the deployment of the equipment and its operation, to fully integrate with the nuclear plant‘s own Emergency Plans.

Furthermore, at Tecnatom’s facilities, the ESC has a team of technicians who are responsible for the maintenance and regular testing of the equipment, in addition to support teams who enable us to respond to any unlikely emergency 24 hours a day, 365 days a year.

Tecnatom has been providing support to the operations of Spanish nuclear plants since it was created over 60 years ago. Among the noteworthy services provided within the emergency sector are the Dosimetry Service, the Emergency Response Centre (ERC) and the ESC.

The dosimetry service, authorised by the Nuclear Safety Council, provides on-site support to nuclear plants during normal operation and emergencies for all aspects related to the control of internal personnel dosimetry.

For its part, the ERC provides technical support to nuclear plants for the administration and management of emergencies with specialist support in various areas such as operations, radiation protection, operational experience and severe accidents etc.

Tecnatom also develops emergency plans and their respective associated procedures, in addition to severe accident management guidelines, emergency service personnel training and the implementation of normal, abnormal and emergency operational procedures. We also collaborate on international nuclear emergency projects, being recognised as a global industry leader.

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

NEXA™ Will Leverage Companies’ Expertise in Technology, Training and Operations Atlanta, Ga. – April 18, 2023 – Westinghouse Electric Company, Tecnatom and Accelerant Solutions announced

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!