Enusa and Tecnatom have carried out the first inspection of nuclear fuel using the new SICOM SIPPING IN-CAN equipment. This equipment has been developed for the detection of fuel assemblies affected by leakage of some kind after having been stored in the fuel pool for several years.

Enusa and Tecnatom have carried out the first inspection of nuclear fuel using the new SICOM SIPPING IN-CAN equipment. This equipment has been developed for the detection of fuel assemblies affected by leakage of some kind after having been stored in the fuel pool for several years.

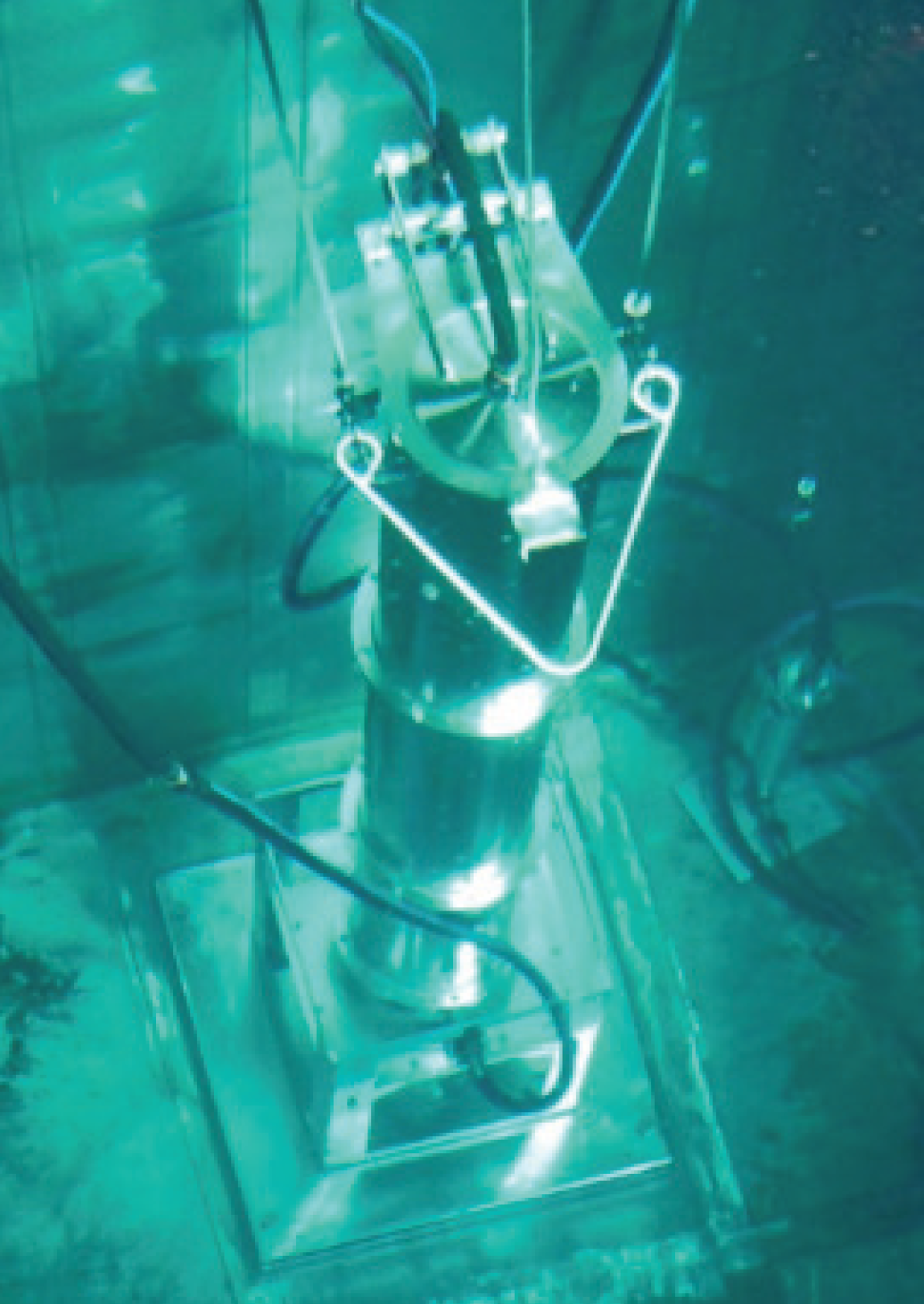

This is a portable system especially designed for PWR and BWR fuel in different configurations that allows for simple adaptation to the designs of different nuclear power plants. It consists of a modular container especially designed to house the fuel assembly in its interior and a pumping unit. Outside the water, the equipment includes a processing and radiation detection unit.

The fuel assembly in inserted in the container and a sample of the water from its interior is pumped to the processing unit. This pumping generates a vacuum inside the container that allows the fission gases to emerge from the fuel assemblies if any of them presents any leakage, the radiation detection unit being in charge of confirming such assembly leakage.

This initial inspection campaign took place at Almaraz nuclear power plant and was the first of a series of campaigns aimed at classifying the integrity of the fuel at the Spanish plants. The campaign increases the offer of fuel inspection services and equipment made by Enusa and Tecnatom, the SIPPING IN-CAN equipment joining the rest of the SICOM equipment suite, especially designed for the inspection of different aspects of irradiated nuclear fuel.