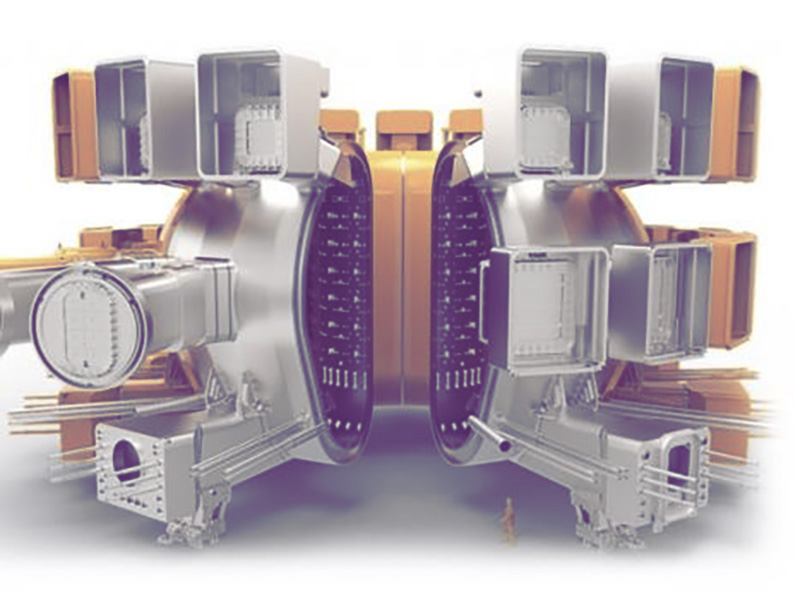

The International ITER fusion project under construction at Cadarache (France), has a reactor vessel of highly complex design and geometry, made up of multiple components that need to be assembled. A crucial part of the assembly process is the quality control of the different types of welds that are to be carried out.

The International ITER fusion project under construction at Cadarache (France), has a reactor vessel of highly complex design and geometry, made up of multiple components that need to be assembled. A crucial part of the assembly process is the quality control of the different types of welds that are to be carried out.

The Spanish company ENSA, one of the two companies in charge of the overall assembly of the reactor vessel, has requested Tecnatom to design and supply different items of inspection equipment for the control of the vessel welds using non-destructive testing techniques.

Tecnatom will be in charge of supplying four different automatic systems for the inspection of the main reactor vessel welds: the welds joining the different sectors of the vessel and those of the vessel inlet ports (port plug).

The supply of this equipment is additional to other activities being performed by Tecnatom within the framework of this international project, such as the non-destructive testing of the toroidal coil precompression rings.