Tecnatom presents two new artificial vision technology developments with multiple applications in the field of inspection. These are known as uDIM and uVIS and are the first commercial products to emerge from the DIRAC project for the development and research of metrology techniques applied to the nuclear sector. The aim of this project is to innovate using optical technologies to improve critical processes relating to nuclear safety.

Tecnatom presents two new artificial vision technology developments with multiple applications in the field of inspection. These are known as uDIM and uVIS and are the first commercial products to emerge from the DIRAC project for the development and research of metrology techniques applied to the nuclear sector. The aim of this project is to innovate using optical technologies to improve critical processes relating to nuclear safety.

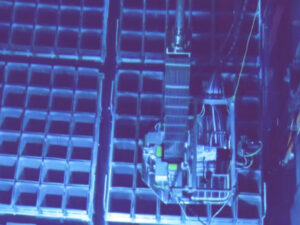

These two first applications have been incorporated in the SICOM-COR fuel inspection equipment. This equipment constitutes an autonomous system that to date has been used to characterise the oxide layers on the peripheral rods of fuel assemblies using the eddy current technique. Thanks to the progress made in the DIRAC project, the equipment has undergone a technology update that allows it to be used also to determine the diameter of fuel rods with a high degree of accuracy.

With this in mind, the equipment incorporates a new independent module, uDIM, integrated in the mechanical architecture of the SICOM-COR equipment and made up of a series of lenses with automatic focussing, measuring sensors and LED lighting. The system has also been designed to withstand high radiation fields and be able to operate at very short distances from the fuel assemblies. Likewise, it incorporates advanced signal processing systems that make it possible to minimise the effects of water disturbances.

The SICOM-COR equipment also incorporates a new development, uVIS, which provides real-time video images during inspections and is part of a new visual inspection concept developed by Tecnatom for nuclear applications. This consists of high definition cameras coupled to a shielding system that allows for operation in high radiation fields.

This update is part of the continuous evolution of Tecnatom’s inspection equipment, aimed at enhancing the characteristics of characterisation campaigns, reducing inspection times and improving the efficiency of the processes.