Production activities have been particularly intense in recent weeks, since three new items of equipment have successfully passed their Factory Acceptance Tests (FAT).

Production activities have been particularly intense in recent weeks, since three new items of equipment have successfully passed their Factory Acceptance Tests (FAT).

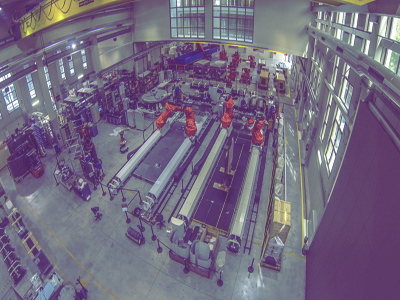

Two of these systems, destined for an important international research centre, have adopted different architectures in keeping with the needs and requirements of the client, but with the common objective of performing UT inspections of large and almost flat composite material parts in the aeronautical industry. One of the systems is made up of two robots mounted on rails, while the other consists of a robot installed on a gantry with two external axes (x & y).

A third dual robot system providing multi-technique inspection possibilities (TTU + PE) has also recently completed factory testing. This system has a high degree of technical complexity, integrating three types of electronics for ultrasonic inspection by means of conventional probes, using the phased array technique, and others with a high dynamic range allowing for management of the different characteristics of the materials of the parts to be controlled. This equipment is outstanding also because it offers a high level of interaction and dialogue with the plant management systems, thus responding to the increasingly widespread digitalisation of factories.