Tecnatom presents its new TECTUS system for the automatic inspection of BWR reactor nozzle welds. This equipment will make it possible to reduce both inspection times and radiation doses. It will also allow the productivity of this type of inspection services to be increased and their quality to be improved.

Tecnatom presents its new TECTUS system for the automatic inspection of BWR reactor nozzle welds. This equipment will make it possible to reduce both inspection times and radiation doses. It will also allow the productivity of this type of inspection services to be increased and their quality to be improved.

This new equipment also makes it possible to reduce the number of operators involved in its installation and operation, its assembly being accomplished rapidly and in an optimised manner from outside the anti-missile shield without the need for tools and minimising the number of connection hoses.

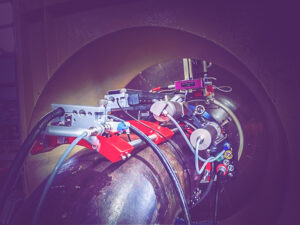

Furthermore, the equipment incorporates technological breakthroughs implying a qualitative leap forward with respect to the state of the art in the inspection of this type of components, applying phased array ultrasonic and ET array inspection techniques without the need to change modules once the system has been installed on the nozzle.

Technically speaking, the system provides axial and circumferential movements and incorporates data acquisition and evaluation equipment developed by Tecnatom. It also includes an operational support video system.

This equipment is the result of Tecnatom’s keen backing for R&D, an area in which every year the company invests approximately 10% of its income, allowing it to continue to create value for its clients while optimising their processes and increasing the safety and efficiency of their plants.