Nuclear power plants are designed to operate for a nominal design period of some 40 years, which may be extended in response to a favourable technical assessment by the regulatory authority of each individual country. For example, in the United States, the vast majority of the plants are licensed to operate for 60 years and several have already requested permission to operate for as long as 80 years. In France, approval has just been issued for more than 30 reactors to continue to operate for up to 50 years. In the case of Spain, the Integrated National Energy and Climate Plan (PNIEC) has set out a schedule for the operation of the country’s nuclear power plants beyond the 40-year period initially contemplated.

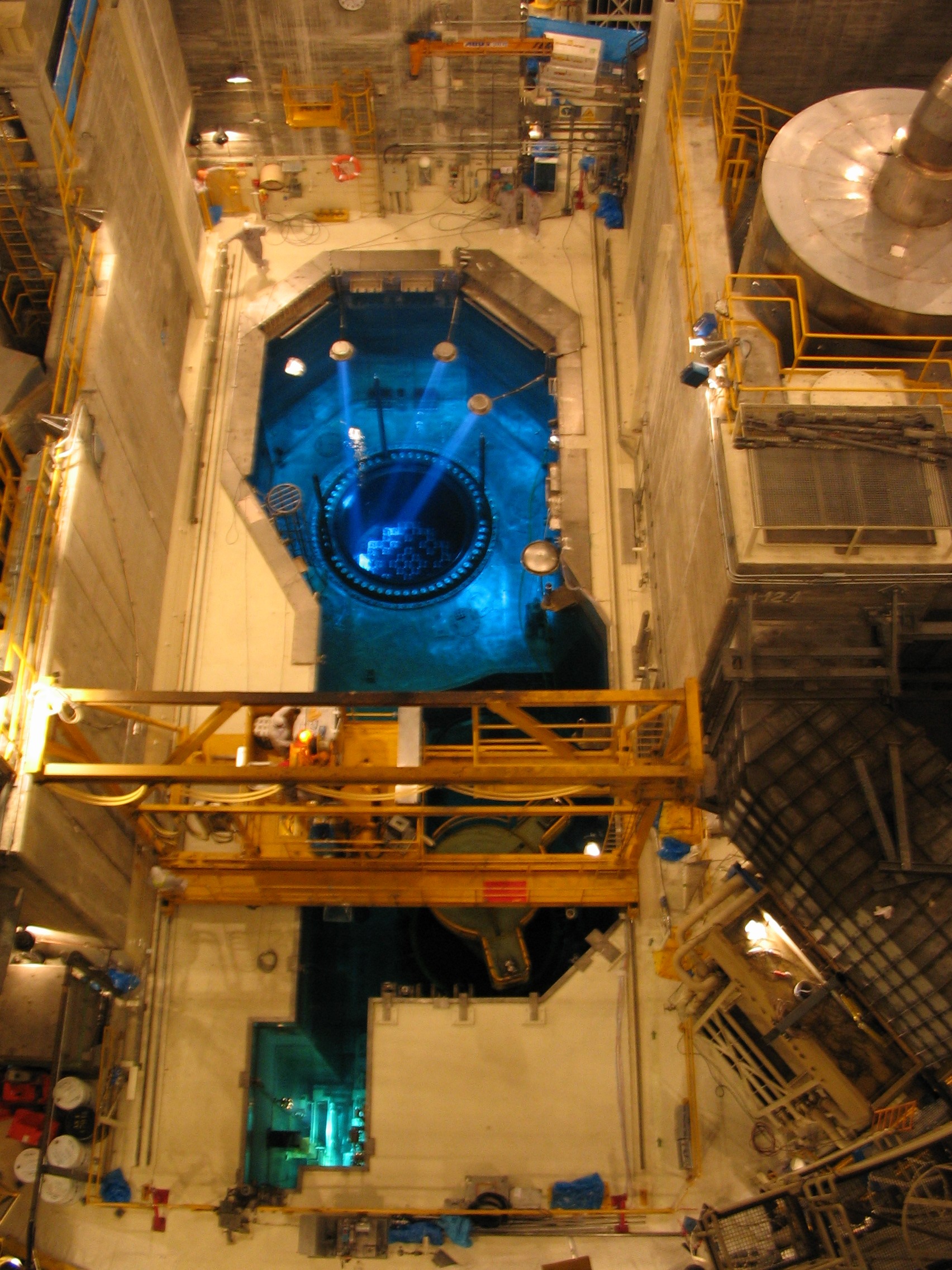

The reactor vessel is one of the critical components within the framework of application of the activities in place for the long-term operation (LTO) of Spain’s nuclear power plants. It is a large steel structure that houses the nuclear fuel in which energy generation takes place, as well a series of complex structures required for its operation. Ensuring the integrity of the vessel and its internal components is a fundamental process for any LTO strategy. In this respect, Tecnatom has been selected for the coordination and performance of the vessel internals engineering and inspection projects for the Spanish nuclear power plants at Almaraz, Ascó and Vandellós.

These activities are carried out in accordance with the most demanding international standards. Specifically, guidelines MRP-227 and MRP-228 of the Electric Power Research Institute (EPRI) are adopted as a framework for performance, these being the reference for this type of inspections in the Institute’s Materials Reliability Program (MRP). These guidelines deal specifically with the following:

- Guideline MRP-227 describes the technical basis for the implementation of the inspection requirements applicable to reactor vessel internals at pressurised water reactor (PWR) plants, which may be subject to any of the potential degradation mechanisms during LTO.

- Guideline MRP-228, for its part, provides the requirements for the non-destructive testing (NDT) methodologies used in the inspection of reactor vessel internals.

The objectives of these projects led by Tecnatom are as follows:

- To gain insight into the actual status of the plant structures, systems and components with a view to considering the hypothesis of operating beyond the 40 years initially contemplated.

- To be part of the ageing management programmes (AMP) of the plants involved in the project, which were drawn up in accordance with Nuclear Safety Council Instruction IS-22 on safety requirements for nuclear power plant ageing management and long-term operation.

The scope of the first project includes upper internals components, such as the control rod guide tube guide plates and the welds of the lower flanges of these tubes.

The second project focusses on lower internals components, such as the lower internals structure welds, the bolts joining the neutron flux deflector plates to the deflector support structure and the vessel internals holding spring.

The following are particularly noteworthy among the activities to be carried out as part of these projects:

- Engineering activities for the development of acceptance criteria for the aforementioned components.

- Validation activities for the inspection techniques to be used in accordance with the Spanish standards and the aforementioned EPRI reference guidelines.

- Inspection activities, using high-tech inspection systems specifically developed for the aforementioned components.

Tecnatom’s experience, gleaned over several decades of performing NDT activities relating to the critical components of nuclear power plants, positions the company as a reference at international level for this type of activities. Indeed, guaranteeing the safety of the plants is our top priority, in keeping with our mission and our commitment to our clients.

Authors: Pedro Trueba / J. Ramon Gadea