Today’s society is immersed in the so-called digital transformation, which, since a few years ago, is changing the rules of the game in all areas.

TecOS

Digitization in maintenance and inspection

All existing systems, components and structures in an energy or industrial installation, depending on their design, construction and environmental and operating conditions, are affected, by some form of degradation and aging thus varying its operational life.

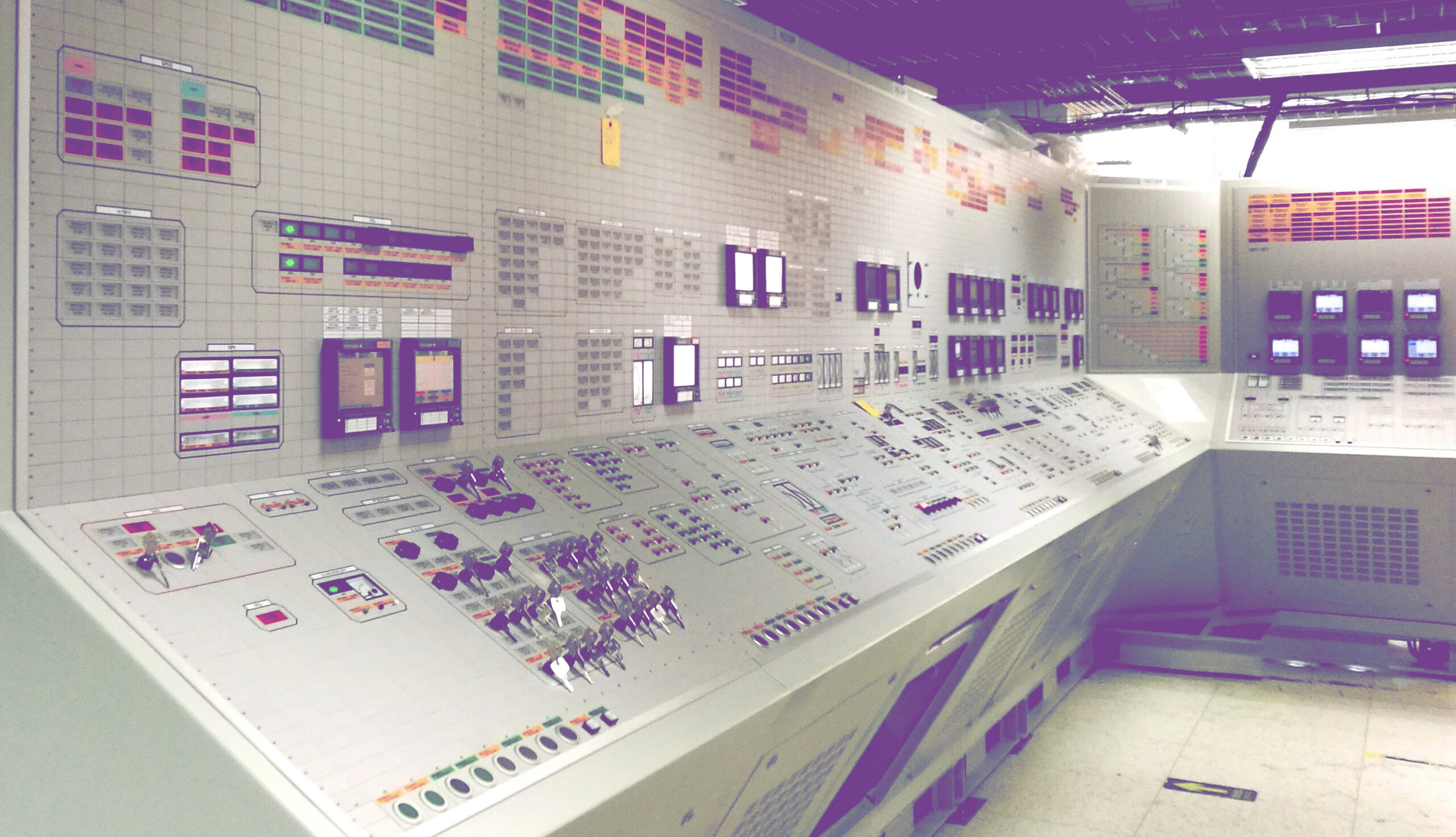

Smart Interfaces

The information that is displayed in current control rooms from a great variety of industries, in monitoring centers, and in results reporting is representative of a “classic” form – based on digital indicators and trend graphs.

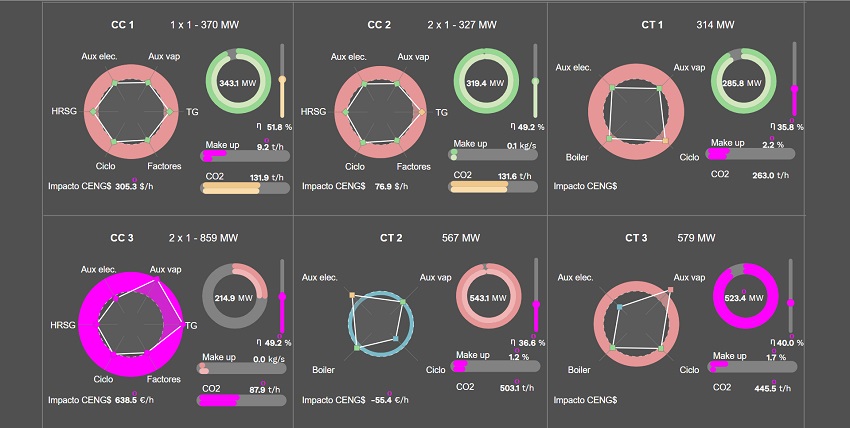

Performance monitoring

Monitoring systems are becoming part of the digital transformation which is currently taking place in the industry. The monitoring of any process consists of gathering information with the objective of detecting possible anomalies or malfunctions. Current technology allows monitoring systems to observe the main magnitudes of any process, remotely and online, using communications. The monitoring … Read more

Predictive monitoring in Tecnatom

Data can provide great value to maximize the efficiency of industrial systems, thanks to the technological revolution centred on the information management and automatic analysis.

Tecnatom inaugurates its Monitoring Centre

Tecnatom has inaugurated its new monitoring centre to provide monitoring and diagnostic services aimed at optimising the operation and maintenance of our client’s power plants.

Tecnatom consolidates its presence in the Chinese nuclear program

Tecnatom is continuing to consolidate its control rooms activities in the ambitious Chinese nuclear program.

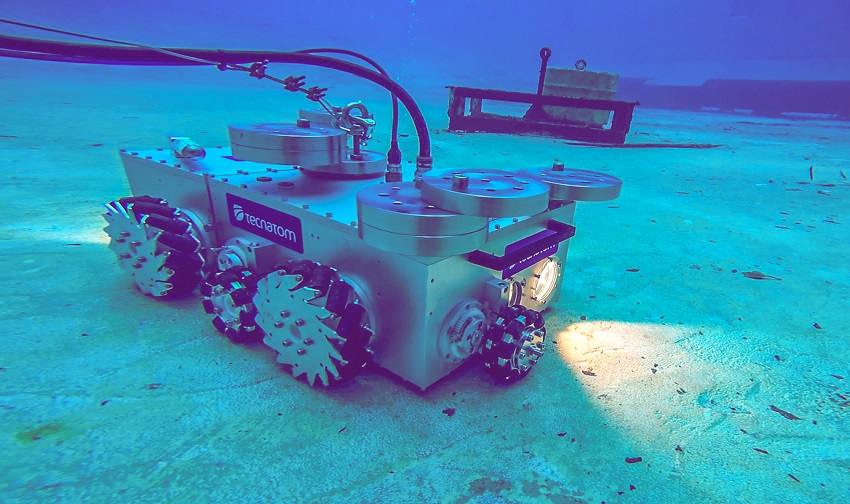

Tecnatom and the new RITA system

Tecnatom has developed a new automatic system to carry out internal inspections on tanks without having to drain them. The new RITA system has already been tested in the Vandellós nuclear power station to inspect the JET01A fuel-oil tank