As was explained in the first article in this series, which dealt with non-destructive testing, ultrasound can be transmitted through a medium, be it gaseous, liquid or solid.

However, they experience special difficulty when it comes to passing from one medium to another if these present characteristics as dissimilar as air and metal. For this reason, coupling materials are normally used, such as water or gels, as they aid the transmission of ultrasounds, avoiding the need for them to pass through the air.

Occasionally, the use of this type of coupling medium is absolutely prohibited, and for these cases Tecnatom offers alternatives such as the use of Dry-Coupled Wheel Probes.

What are Dry-Coupled Wheel Probes?

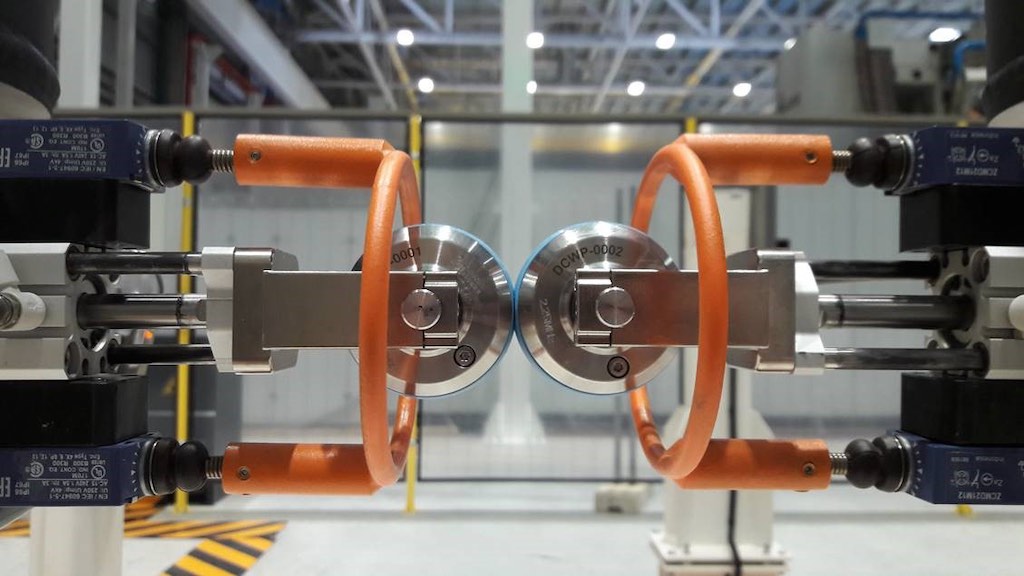

Dry-Coupled Wheel Probes are sensors made up of an ultrasonic transducer surrounded by a coupling medium inside a hermetically sealed chamber made of a special rubber that guarantees that no leakage will be able to moisten or stain the part inspected.

These components installed in a wheel system are optimised to maximise ultrasonic transmission. For the operation of these sensors it is critical to achieve a connection that allows for rotation and maintains high performance while the sensors move across the part.

What are the advantages of Dry-Coupled Wheel Probes?

The key feature of coupled wheel probes is that they are a combination of a high quality probe and perfect mechanical coupling, in addition to which are the characteristics of the material of the outer chamber, which is required to couple the sensor to the part maintaining a high degree of ultrasonic signal transmission.

These sensors are capable of operating over a wide range of frequencies depending on the needs of the application, even with low frequencies in the case of highly attenuating materials such as some of those used in the aerospace sector: honeycomb or foam.

Despite its being based on a concept that has been around for many years in the ultrasonic industry, Tecnatom has achieved a significant improvement with this design, which stands out for guaranteeing a better signal than all those competitor sensors with which it has been compared (+6dBs)

Why use Dry-Coupled Wheel Probes?

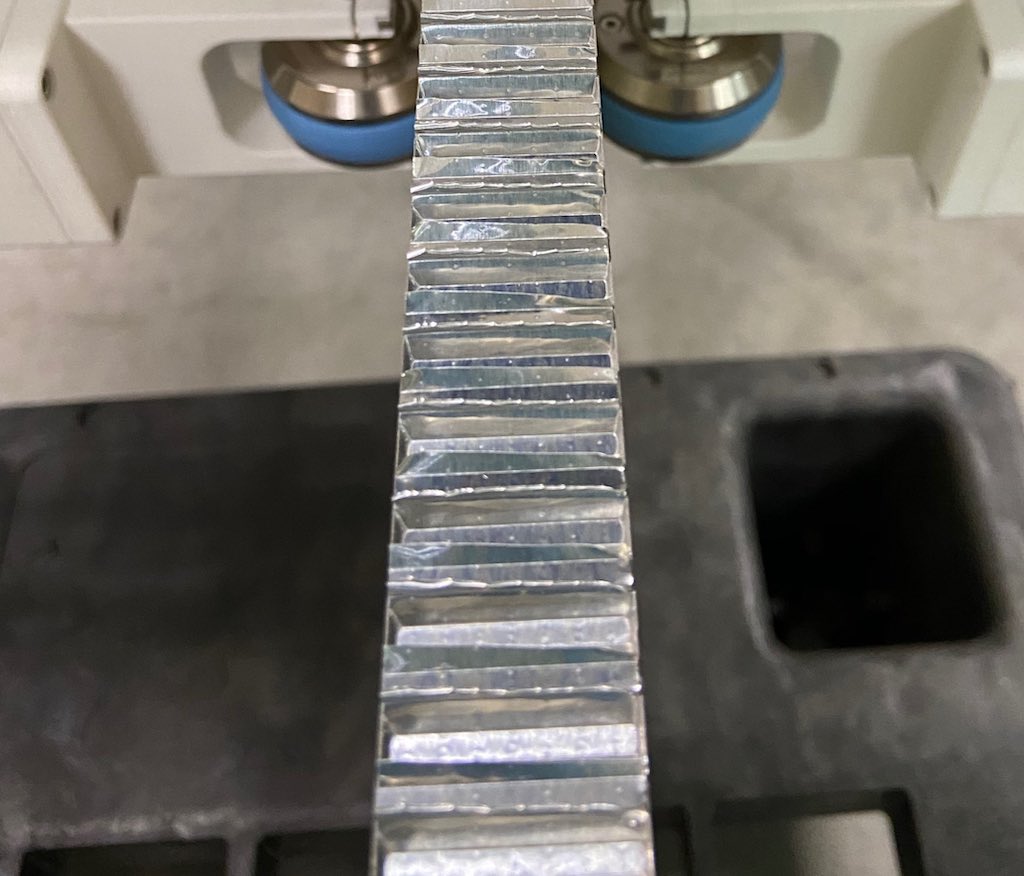

These probes are currently used for the inspection of aerospace parts, specifically parts of the Ariane 6 launch vehicle (Airbus Defense and Space).

The sensors, integrated along with the SONIA BLUE specialist electronics for the acquisition of ultrasonic data in a TAURUS robot-operated cell, go to make up a robust multi-method automatic inspection system.

This system allows the quality of the parts of the launch vehicle (or launcher) to be guaranteed quickly and reliably, since it is capable of detecting minor manufacturing flaws in honeycomb material with a resolution of 1mm.

Thanks to this type of systems it is possible to guarantee the high standards of quality demanded by sectors in which the safety requirements are particularly stringent, such as the aerospace or nuclear industries. This is an example of how the combination and integration of different technological components can achieve results at the forefront of non-destructive testing (NDT).

Authors: Elena Cabellos, Alfonso Laín