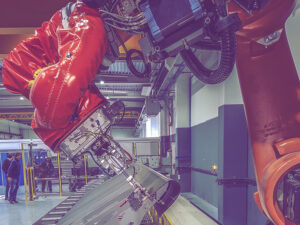

Tecnatom has extended the capacities of the TAURUS inspecion system supplied to the Belgian firm SONACA, integrating a thermography system developed by the client in a simple and flexible manner and with minimum impact.

Tecnatom has extended the capacities of the TAURUS inspecion system supplied to the Belgian firm SONACA, integrating a thermography system developed by the client in a simple and flexible manner and with minimum impact.

Infrared thermography is a contact-free non-destructive testing technique that determines the temperature of the surface of a body by picking up the infrared radiation emitted by it.

When the heat flux of a material is altered by the presence of anomalies or defects, this causes contrasts in temperature at the surface that may be detected by an infrared camera.

In order to integrate this solution in our aeronautical inspection systems, developments have been applied affecting different areas of the system (new hardware and software) that implement the technology required for the management of the thermography system, making the generation of control commands transparent to the user.

This technology, developed by Tecnatom, allows the thermography equipment to be managed and controlled fom the inspection path itself, without affecting the previously existing functionality. It is a flexible and scaleable solution that increases the multi-technique inspection capacities of robot-operated cells based on RABIT technology, and that may also be extrapolated to other inspection techniques (metrology, shearography, etc.).