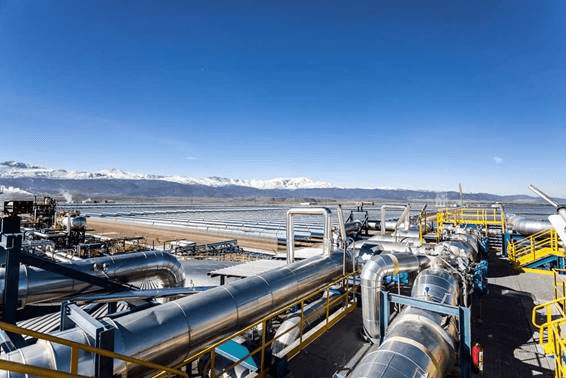

Solar-thermal power plants are based on what is probably the most complex generating technology in the renewable energy sector. This type of plant uses energy from the Sun to heat a fluid, which is in turn used to move a turbine. A specific feature that makes these plants particularly interesting is their capacity to store energy in tanks of molten salts, this allowing them to produce electricity round the clock.

The surveillance and correct maintenance of pressurised equipment at facilities of this type is vitally important to ensure their correct operation, and also to prevent serious consequences in the event of any failure.

The standards in force require such equipment to be subjected to hydrostatic tests (level C) every 6 to 12 years, depending on their category. These hydrostatic tests consist of subjecting the equipment to high pressure in order to verify their structural integrity, thereby guaranteeing suitable levels of safety and strength.

What difficulties does the performance of this test pose?

This is a complex test that requires special attention to be paid to guaranteeing the insulation of the equipment being tested, in order to prevent damage to this equipment and to others connected to it. incompatibilities may also be discovered between the test fluid and that used in operation, which may lead to subsequent problems.

Are there alternatives to hydrostatic testing?

The standards in force contemplate the possibility of performing replacement tests instead of the hydrostatic test. In many cases it is possible to guarantee the structural integrity of the component through the use of different Non-Destructive Testing techniques since, if there are any faults in the component, the techniques proposed will allow them to be identified and mitigation and monitoring measures to be taken to prevent the deterioration of their structural integrity.

Can Tecnatom help you with the design of Level C Hydrostatic Test Replacement Tests?

Tecnatom has more than 60 years of experience in the drawing up of inspection plans and integrity studies for the different items of equipment and components found in power plants and industrial facilities, selecting the critical areas of each item of equipment and applying the most appropriate techniques for the detection of any type of defect.

As a result, Tecnatom has the experience and know-how required to draw up replacement test plans for different industries in collaboration with the plants, among them solar-thermal facilities, with a view to obtaining their approval by the Ministry of Industry.