Tecnatom has been selected by the Spanish company Endesa Generación for the performance of a pilot digitalisation project, in this case associated with the predictive maintenance of the main transformer at the San Adriá de Besós combined cycle plant (Spain).

As power transformers are the most critical components of any electricity generation, transmission and distribution system, any operational failure might have a negative impact on service, as well as the high repair cost and delivery time required for a new transformer.

In view of the above, it is vital that special attention be paid to transformer maintenance and that advanced tools be identified allowing potential faults to be detected in the early stages. The aim is to minimise the impact that any incident might have on the normal operation of the electrical system.

Innovative systems for electrical digitalisation

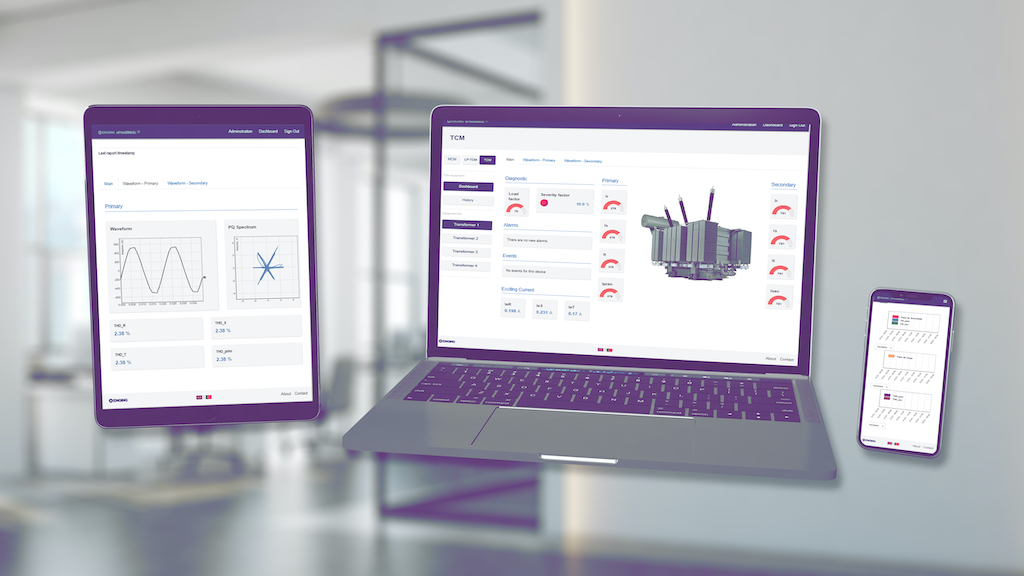

In this framework, the collaboration between Tecnatom and Enging made it possible to provide a highly innovative monitoring and diagnosis system (EMS-TCM) capable of measuring the most representative electrical magnitudes in real time and in a non-invasive manner, automatically assessing the operational status of the transformer. This early detection allowed transformer maintenance actions to be suitably planned and performed, thereby avoiding non-scheduled outages.

Furthermore, this type of predictive monitoring tools prevents initial damage from spreading to other plant components in good condition, thereby reducing the eventual repair costs that a transformer event might give rise to.

The performance of this innovative project marks a new milestone in the collaboration between Endesa and Tecnatom in the field of digitalisation, new technologies and predictive maintenance.