At the end of October last, the factory acceptance testing (FAT) of the fresh fuel rod scanner (TESCAN) that Tecnatom and Enusa are supplying to the company CONUAR-Fae took place at the Tecnatom facilities in San Sebastián de los Reyes.

At the end of October last, the factory acceptance testing (FAT) of the fresh fuel rod scanner (TESCAN) that Tecnatom and Enusa are supplying to the company CONUAR-Fae took place at the Tecnatom facilities in San Sebastián de los Reyes.

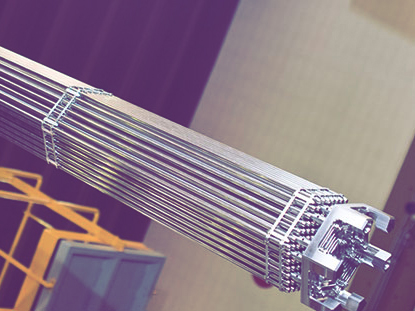

The tests included both the rod handling system and the sensors for the measurement of gadolinium enrichment and content.

The TESCAN equipment is used for quality control during the nuclear fuel manufacturing phase, allowing multiple critical parameters to be controlled. In this specific case, the equipment will be used for verification of the fuel manufactured in Argentina for future CAREM model reactors.

This 25 MWe reactor, through which Argentina seeks to reaffirm its capacity to design, develop and start up nuclear power plants, stands out as an alternative at world level in the segment of low and medium power modular reactors. This type of reactors offers great potential for the supply of electricity to areas located far from major cities or industrial centres with high levels of electricity consumption. It also offers other advantages such as the capacity to supply desalination plants or the production of steam for various industrial uses.

Following the FAT tests, the equipment will be sent to the fuel manufacturing facility located in Buenos Aires, and the project will be completed with SAT testing with test rods and assistance in its implementation in the production process. This supply is part of the numerous activities that Tecnatom is carrying out in the Argentinean nuclear programme, in which the company collaborates closely with the Atucha and Embalse nuclear power plants.