Check valves act as safety devices, allowing flow to pass in one direction but preventing it in the reverse direction. These valves are actuated by the flow through them. Their basic functions are isolation of the containment at nuclear power plants, the separation of systems operating at different pressures and the protection of turbine or motor-driven pumps at industrial facilities. Given the intrinsic characteristics of the operation of these valves, any failures or breakdowns affecting them may remain hidden during operation of the plant, affecting its safety, as a result of which they are periodically diagnosed.

Check valves act as safety devices, allowing flow to pass in one direction but preventing it in the reverse direction. These valves are actuated by the flow through them. Their basic functions are isolation of the containment at nuclear power plants, the separation of systems operating at different pressures and the protection of turbine or motor-driven pumps at industrial facilities. Given the intrinsic characteristics of the operation of these valves, any failures or breakdowns affecting them may remain hidden during operation of the plant, affecting its safety, as a result of which they are periodically diagnosed.

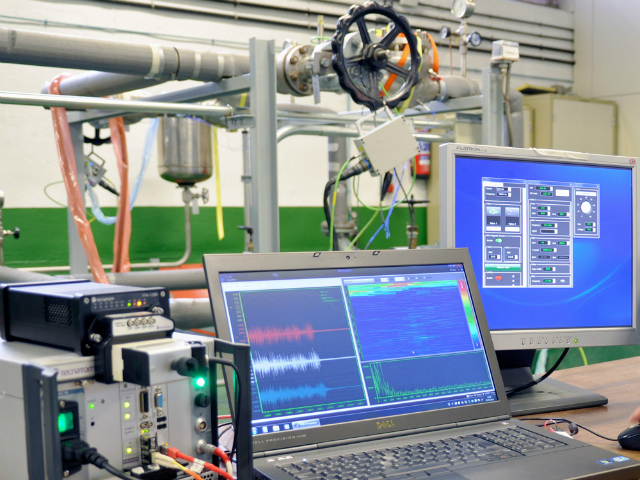

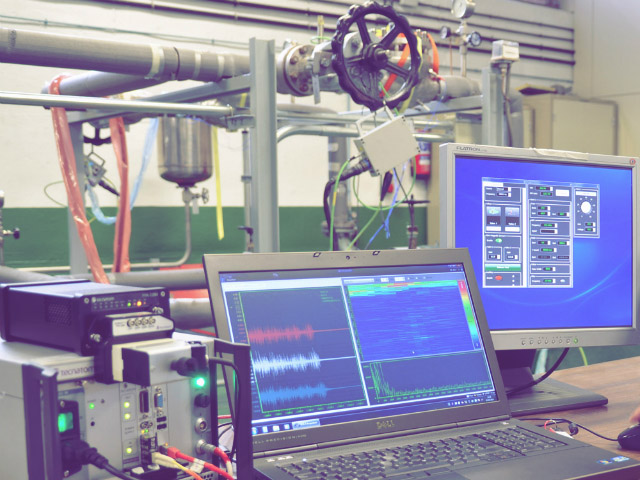

Tecnatom has developed a new technique for the diagnosis of check valves, based on phased array ultrasonics. The ultrasounds propagate through the interior of the valve, scanning the positions of the internals and the trajectory they should follow on actuation of the latter. This new technique provides qualitative information on the operability of the valve and the state of its internals, thus complementing the system used to date by Tecnatom, the VITE-R 2.0.The VITE-R 2.0 check valve diagnosis system is capable of analysing two valves simultaneously, for which it is equipped with five channels per valve: three accelerometer channels, a magnetic sensor channel and an auxiliary channel that may be used to couple a displacement sensor to the system. Thanks to the modularity, versatility and flexibility of the new Tecnatom ultrasonic equipment, SONIA + FPA-128M, it has been possible to integrate the new phased array technique in the VITE-R 2.0 system.

From the functional point of view, the incorporation of ultrasonics in the VITE-R 2.0 system allows for dynamic tracking of the position of the internals throughout the entire actuation of the valve and enhances the capacity to analyse valve operability and the performance of the internals. Likewise, the incorporation of phased array technology makes it possible to increase the reliability of the results and the efficiency of the process in the inspection of stainless steel valves, where the magnetic fields technique was not conclusive.