INTRODUCTION

Nuclear energy is recognized for most countries as part of the solution to climate change. One of the main challenges of nuclear energy is the large initial investment required and the extensive time required for its design, construction and licensing. For this reason, there is great interest worldwide in the development of reactors that allow reducing the initial investment with simpler designs, based on passive safety systems, with the ability to regulate the load and reduce construction times. Those known as SMR (Small Modular Reactor) are the nuclear industry’s solution to this need.

In addition to the aforementioned advantages, SMRs have less need for heat removal, as their cores are smaller, and the consequences of hypothetical accidents are lower.

These SMRs can have diverse applications such as to provide electricity in remote areas, replace fossil fuel plants, hybridize with renewable energies, generate hydrogen, supply energy for water desalination plants, deliver heat for district heating applications or industrial processes.

TECNATOM’S EXPERIENCE IN THE DESIGN OF SMRS

Tecnatom is participating in the design of different SMRs in the areas of Instrumentation and Control (I&C) and Human Factors Engineering (HFE). The design of SMRs presents different technological challenges in these areas associated with economic and technological feasibility, both being related.

Economic viability depends on maintaining a competitive CAPEX and OPEX with other technologies.

The main cost during the operation and maintenance of a reactor is due to the personnel required to carry out these tasks. SMRs are less powerful than conventional nuclear power plants, so in order to keep these costs at acceptable levels, they must be operated and maintained with personnel appropriate to their size. This goal can be achieved with innovative operating and maintenance concepts. This poses technological challenges to increase automation and support the digitization of common and repetitive processes, allowing staff to focus on higher value tasks.

In addition, it must be taken into account that the impact of I&C on the CAPEX of a conventional reactor is around 5%, which becomes 15% of the CAPEX of an SMR as the need for I&C equipment (sensors, wiring, control systems, display equipment, etc) is not reduced with the size of the reactor.

CAREM-25 CASE

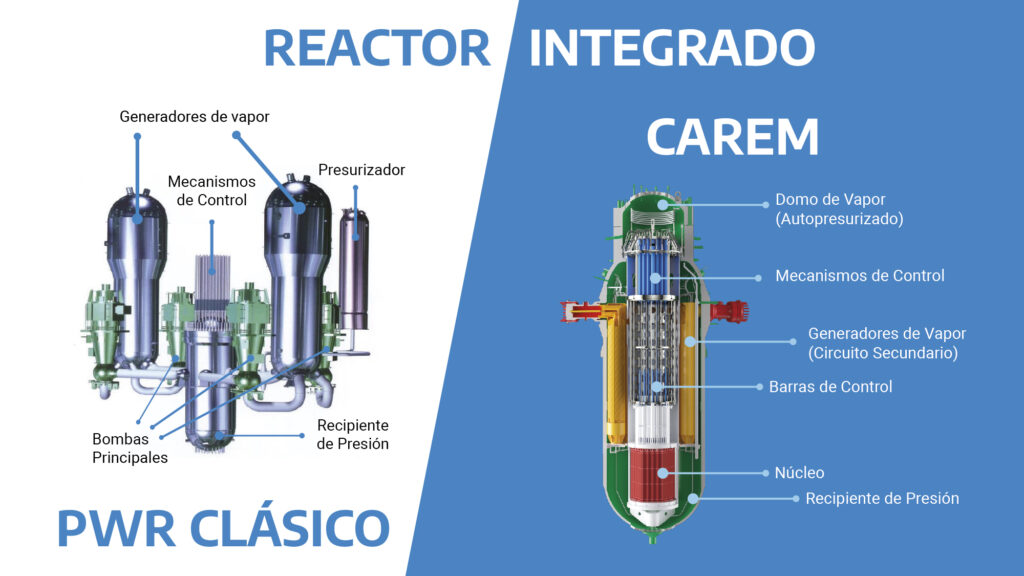

Tecnatom collaborates in the design of the CAREM25 (Argentine national project developed by the CNEA) in the I&C and HFE areas. It is a PWR-type reactor, with some features that simplify the design and improve safety. This video explains in detail the design of the CAREM.

The benefits of this simplified design is that components, and thus potential causes of failure, are eliminated. In addition, since pipes with water of the primary circuit do not come out of the vessel, the chances of a coolant loss accident are greatly reduced.

In the design of safety systems, the guidelines of the nuclear industry are followed, applying the Principles of Defense in Depth (DenP) according to the WENRA proposal, which implies defining 5 levels of defense based on plant conditions and postulated initiating events.

I&C architecture design

The General Control and Monitoring System of the Plant (SCMGP) is in charge of measuring the process parameters to identify the initiating events, act automatically on the necessary equipment and/or inform the operators that they may, in certain circumstances, act on components manually. In addition, there are passive safety functions that act without having to be activated when certain conditions are reached.

The design of the SCMGP architecture must satisfy the requirements of reliability, independence, redundancy, and tolerance to common cause failures by the application of the DenP Principle.

The methodology followed in the design is based on the safety functions of the plant and their relationship with the postulated initiating events. In accordance with the security category of the security function, and the level of defense in depth in which the function operates, the requirements of the control system where the security I&C function is implemented are defined, as established by the IAEA safety guidelines and IEC (International Electrotechnical Committee) standards.

CONCLUSIONS

The CAREM project exemplifies how, with a simpler design based on intrinsic and passive safety, it is possible to increase safety and reduce costs by requiring fewer components.

The CAREM will allow to supply electricity to remote places in a reliable and economically viable way, allowing the development of industry in those places, or to be used for water desalination, among other applications.

Click this link for more information on Tecnatom’s experience in nuclear control rooms