The new combined cycle plant simulator developed by Tecnatom for Gas Natural Fenosa, has attained the status of “suitable for training”. This simulator project, which is based on the reference of group 1of the Cartagena plant, has overcome a number of technological challenges, due to the high degree of automation of combined cycle plants, and in particular those incorporating Alstom technology.

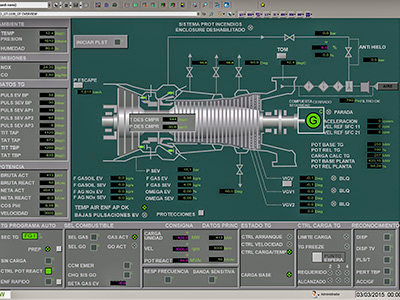

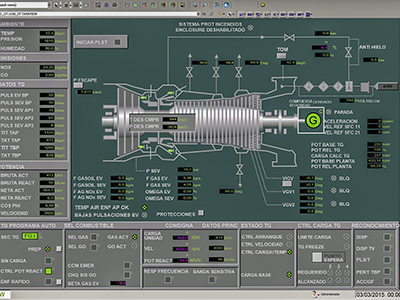

The scope of the project included: dynamic modelling of the main plant systems (gas turbine, recovery boiler, water-steam cycle, steam turbine, group BOP, common BOP and electrical systems) and complete modelling of the control and protection systems and graphic operations interface, with the same scope as at the reference plant. Furthermore, a performance analysis module similar to the one available in the control room was included.

The simulator has been designed to cover various plant operating ranges, including start-up from any temperature condition (cold, warm, hot) to base load, as well as shutdown from base load to cold shutdown and including all intermediate conditions. The scope also includes a large number of generic and specific faults allowing for training on any contingency outside normal operation.

The project has been carried out using technology developed entirely by Tecnatom, ranging from thermohydraulic models to signal logic models and including a tool capable of automatically generating training and self-assessment scenarios.

The delivery of this simulator comes in the wake of others for Alstom type plants belonging to Gas Natural, such as Hermosillo, in Mexico.