Human Factors Engineering (HFE) is a multidisciplinary field of study whose goal is to optimize performance and reduce human error. To do this the HFE incorporates the methods and principles of various branches of knowledge such as engineering, physiology, medicine, psychology and sociology.

How HFE is applied

This discipline, whose application is unavoidable in those sectors of the industry where safety is a priority (nuclear, aeronautical, defense, aerospace) is becoming more and more widespread, considering the great advantages that its application entails.

One of the main fields of application of the HFE is related to the design of the interfaces (panels or screens) of all types of Control Rooms, through which communication is established between the personnel and the machines (which are controlled and remotely supervised) in order to improve the interaction between man and machine.

When designing Control Room interfaces applying HFE principles, it is recommended to follow a program based on international standards, whose degree of completeness is modulated according to the importance of the designed interface. The most widespread models of HFE programs suggest:

- The study of positive experiences and mistakes already made in situations or using similar interfaces.

- The analysis of the functions and objectives of our machine or industrial installation, including the study of each one of the systems that compose it.

- The determination of the level of automation, that is, what are the functions that a machine can perform and what the human being taking into account the capacities and limitations of each one.

- The study of the actions that are executed by the human being, analyzing in detail those that may be more critical a priori, more complicated or associated with a more serious consequence due to an error in that execution.

- Determining the number of operators needed as well as the required training.

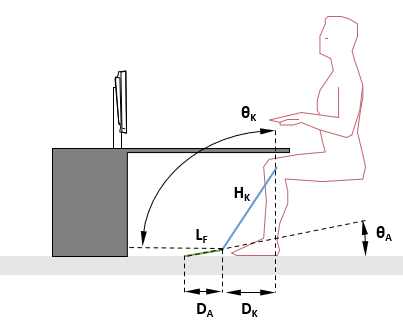

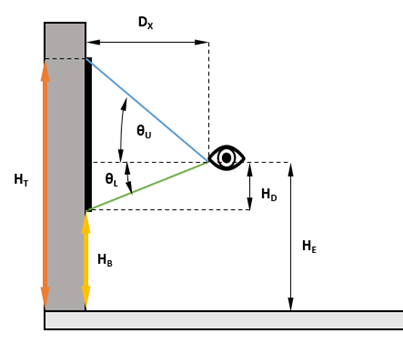

- The definition of the details of the interfaces, considering the physical characteristics of its users, the situations of greatest stress in its use and the characteristics of all its elements, such as buttons, indications, alarms, etc.

HFE also contemplates the verification and validation of the results obtained, to ensure that they meet the specified requirements and the objectives set, before manufacturing an interface or putting a control room into service.

The result of the application of the HFE principles is a control room that is operated in the simplest possible way, is organized with the user’s needs in mind and contains everything necessary to operate a facility safely. Therefore, it is guaranteed that the staff will not have difficulties to operate, minimizing the occurrence of errors or mitigating their consequences.

What is Tecnatom value proposition

Tecnatom’s proposal is based on combining our capabilities in the field of HFE with experience in operation in power plants as well as in other process industries, in order to offer our customers solutions specially adapted to their needs, all this is backed by a company with more than 60 years of experience.

Both the design of a new control room and the total or partial modernization of an existing one represent a complex project that requires multidisciplinary knowledge and enormous capacity. In this sense, and considering the advantages it provides, it is essential to incorporate an HFE study.

During the last three decades we have designed more than 25 control rooms internationally at Tecnatom, including 20 turnkey control rooms for the nuclear sector, as well as developed an innumerable number of projects in the field of HFE. The prestige obtained during this time has allowed us to access the forums and specialist teams of the IAEA, NRC or EPRI, therefore our products comply with all the safety requirements imposed by the market.