The current energy transition brings with it profound changes in the electrical system, – changes which modify the behavior of grid assets and, in turn, come with an increased possibility for incidents and the need for corrective actions to overcome said incidents. One of the most critical assets of an electrical grid are the electrical substations, and it is of utmost importance for their availability to be ensured.

There are simulation-based solutions for training electrical facility employees in order to improve local responses at electrical cabinets and panels, as well as remote operations from a control room. In this way, the technical and practical abilities of teams of workers are strengthened, thus reducing the amounts of time that electrical service is cut and the negative impact brought about thereby – all the while improving electrical installation reliability.

How was this solution detected?

Those in charge of different electrical installations and grid operators identified the need to have a “training simulator” tool to:

- Train their staff members on proper operations at their electrical installations.

- Confirm and set good operating practices.

- Ensure operational effectiveness and installation safety and reliability by standardizing operating modes.

What additional benefits come out of these types of developments?

Other benefits include the reduction of:

- Training costs (operators are trained and certified more quickly).

- Operating errors.

- Recovery times in the event of electrical incidents.

Likewise, these types of solutions can also be used for simulation assisted engineering tasks, such as:

- Verification of operating procedures.

- Operations engineering and design.

- Accident and emergency situation drills.

- Validation of instrumentation and control systems modifications (such as SCADA).

- Assessment of other installation design changes.

What are these types of simulators like?

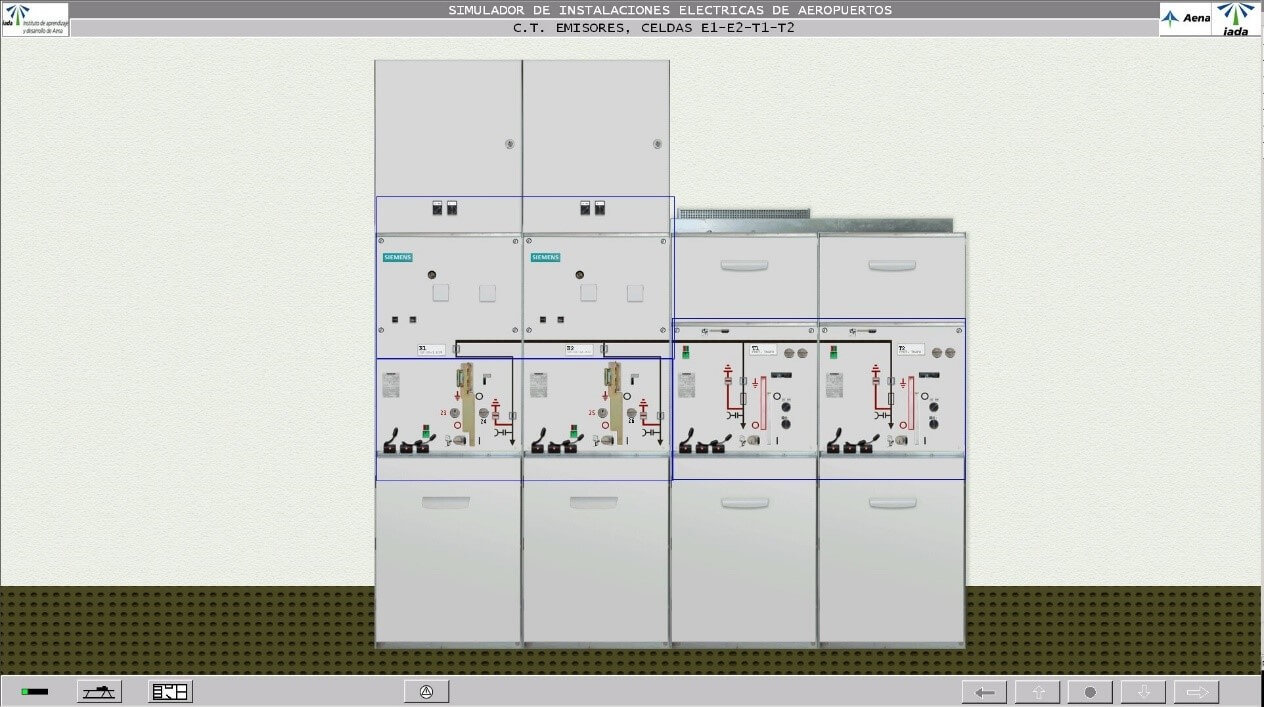

These types of simulators, developed by Tecnatom, cover the full scope of medium- and low-voltage electrical installations, including electrical substations, the operation of electrical equipment such as transformers, busbars, diesel generator sets, high-voltage cabinets, switches, etc.

The installation’s systems and equipment are simulated through tools of the “model builder” variety that allow for the required degree of reliability to be obtained to define simulation maneuvers.

The simulator meets the established physical reliability criteria for the installation’s elements, having a user interface that is based on graphical “virtual panel” displays simulated through photographs. The simulated process can be acted upon.

Set of Cabinets

Another feature of this type of simulator is that it is very much linked to the “GIS” (“Geographic Information System”), which allows for faults to be identified quickly and, in turn, for rapid identification of the equipment to be manipulated.

General Map of Electrical Installations

Conclusions

Use of a simulator at different installations has allowed for an improved level of skill when undertaking different operations in electrical cabinets or with electrical equipment to be identified as one of the advantages of full-scope simulation-based training. This, in turn, has increased confidence and safety significantly when these types of operations must be undertaken – operations which involve a high degree of danger.

This increased confidence, safety, and training of staff members helps to minimize the number of incidents and events that happen in these contexts, thus guaranteeing improved availability to help meet new demands on the grid.