Traditionally, simulators have been constructed as exact replicas of the control room panels, including real instrumentation.

Technology is now available that allows the panels to be virtualised, this providing greater versatility in use for different projects and considerably reducing costs.

What are virtual panels?

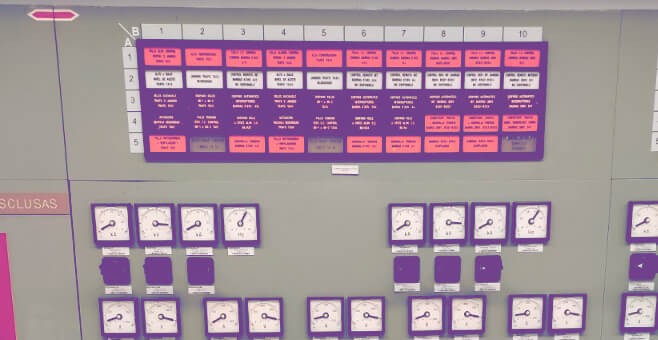

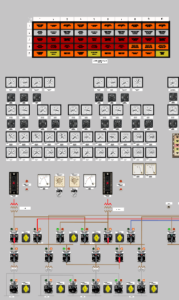

They are software operations interfaces that replicate the hardware panels from where it is possible to interact with the control devices that they house, guaranteeing maximum physical and functional fidelity.

Being a virtual solution, they may be accessed remotely, are easily portable and are developed in a modular fashion, allowing for extensions as new needs arise.

How are they developed?

Firstly, virtual objects of each of the hardware elements mounted on the panel are generated, for example handswitches, pushbuttons, indicators, video recorders, alarms, etc. Subsequently, they are located in the exact position on the virtual panel and finally they are made dynamic by defining the signals required for each position, this allowing for connection with the simulation.

In this respect, within its TEAM integrated simulation environment Tecnatom has developed the TEAM-Sketch tool for the design of virtual panels.

Devices from which to operate and current uses

Virtual panels may be operated from a number of different devices, such as PC’s, Tablets, glasstops or totem panels.

They may be used for different purposes depending on the device from which they are operated:

PC

- Instructor’s consoles: Full-scope simulators (FSS) are equipped with virtual panels replicating the control room from where the instructor may visualise plant status and supervise the activities of the operating personnel.

- Interactive Graphic Simulators (IAS): These simulators are fitted with virtual panels replicating the control room from which all the panels may be operated.

- Airport facility simulators. These simulators allow for visualisation and control using virtual panels of high and low voltage electrical cabinets and general panels.

- Diesel plant simulators. The graphic interface of these simulators is made up of virtual panels replicating the control panels.

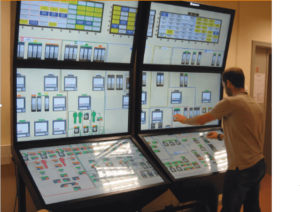

Glasstop

This is a metallic structure with three touch screens that may be used to visualise and operate the virtual panels of panels with consoles and alarm annunciators.

- The simulators of the Trillo, Almaraz, Ascó and Vandellós nuclear power plants are equipped with glasstops allowing for visualisation and operation on control room virtual panels.

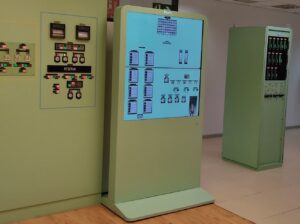

Paneles Totem

These allow auxiliary panels to be simulated via two touch screens. They are connected to the simulation by cable or wifi, this allowing the panel to be moved to any location.

- Ascó NPP is fitted with panel PL-73 and Vandellós NPP with panel A-70. These panels allow for the performance of training sessions and validations in fire-fighting scenarios.

Other possible usage cases

- On-site / in-the-field training. The possibility of loading different virtual panels on the Totem panels, the simple connection with the simulation and the movement of the panel make it possible to practice manoeuvres, verify procedures, etc. on the spot or nearby, all this prior to the performance of the actual test.

- Development of the overall simulator. To accomplish this, several glasstops would be coupled in series to obtain a simulator with virtual panels.

- Validations and analyses prior to installation. Human factors validations, engineering analyses and design modification procedure validations may be carried out prior to the implementation of the change at the facility.