Just as the technical inspection of vehicles (MOT test) is obligatory for cars, the maintenance of the equipment and probes/sensors used for NDT (Non-Destructive Testing) inspections is also an essential activity. In industry, guaranteeing the quality of the components used for the performance of an activity is a key step that is accomplished by the NDT examination of critical components. These tests are a type of legal preventive maintenance that is performed periodically by a certifying body in charge of verifying compliance with safety, reliability and operating standards.

For this reason, the standards require the equipment to be subjected to periodic checks, as they may experience deterioration over time as a result of inadequate operating conditions, damage in transport, etc. These checks also guarantee that the results obtained during inspections are valid and comparable.

What is certification?

Equipment certification is a process in which an instrument is tested and the values obtained are compared to a known standard used as a reference. This allows indication errors to be identified and appropriate actions to be taken to ensure the reliability of the equipment when in use. The certification process must be carried out in a laboratory in which the necessary protocols have been developed.

In order to guarantee the reliability of our inspections, it is necessary to check that the instruments used are in optimum conditions as regards their basic functions. This is an essential activity and is required by our strict safety procedures, since in the field of NDT it is necessary to characterise and verify equipment and probes in order to guarantee their correct operation and offer a quality service.

How do we help you from Tecnatom?

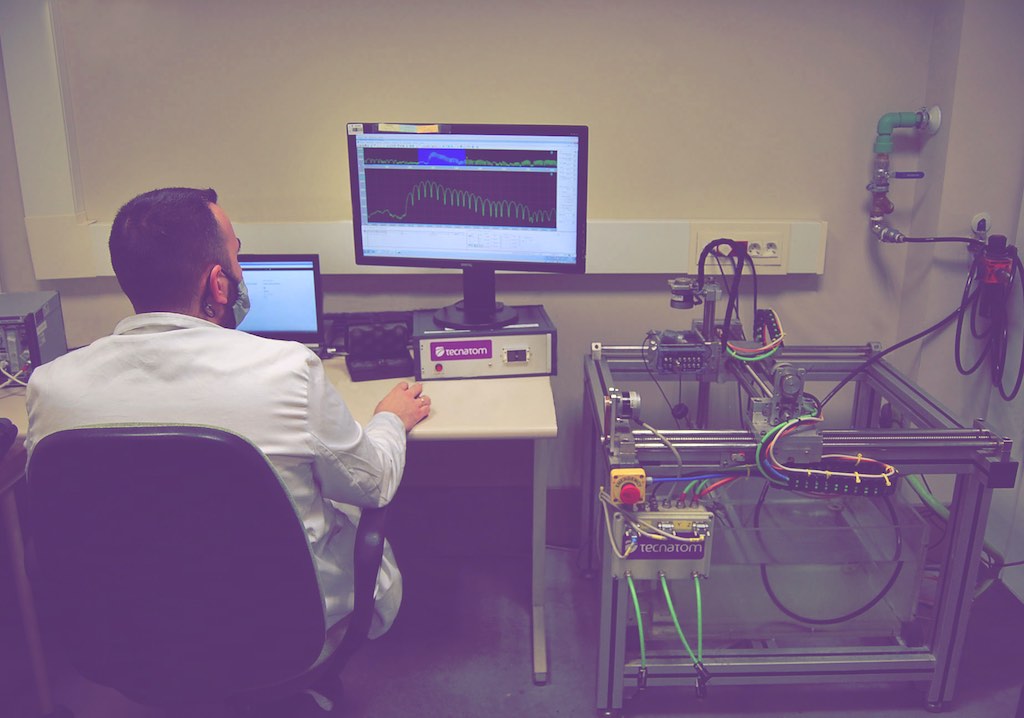

In order to perform NDT tests with the necessary guarantees, both quality and the results obtained by the equipment must be ensured by means of the certification process. This process is certified in accordance with specific standards or voluntarily in order to gain insight into the condition of the equipment and guarantee a quality inspection. Tecnatom possesses suitable resources that allow the company to provide a certification service for both equipment and probes and sensors.

The process is very straightforward for the client, who simply sends his equipment to Tecnatom laboratories. In a short space of time, the equipment is returned with its certification certificates.

This certification service is applicable to a wide range of industrial sectors and, more specifically, calibration certificates may be issued in accordance with all the following standards:

| Phased Array UT Equipment | EN ISO 18563-1: 2015 AITM6-0016/5 2014 |

| Conventional UT Equipment |

EN ISO 22232-1 :2020 AITM6-0013/6 2014 |

| ET Equipment | EN ISO 15548-1: 2013 |

| Phased Array UT Probes | EN ISO 18563-2: 2017 ASTM E2904 -17 AITM6-0016/5 2014 |

| Conventional UT Probes | EN ISO 22232-2:2020 AITM6-0013/6 2014 |