Automated analysis of Baffle Bolts

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

Making the Nuclear Power Plants Safer

Inicio | Nuclear Archives | Fuel Inspection

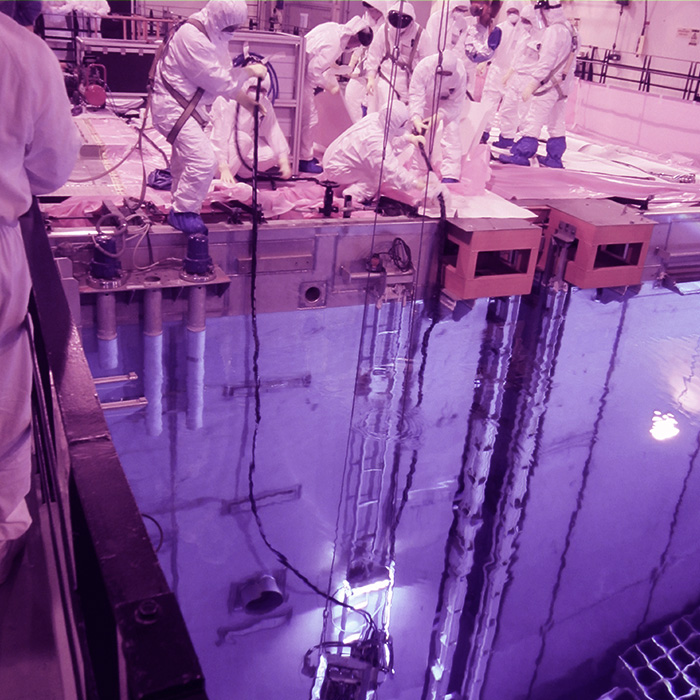

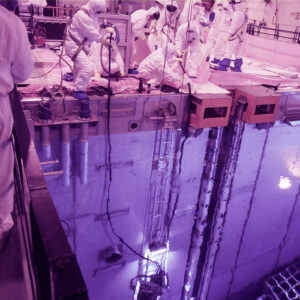

Tecnatom develops technology and renders services for the inspection and characterisation of both fresh and spent nuclear fuel. In order to do this, we have been working in close collaboration with the Spanish nuclear fuel manufacturer ENUSA since the 90s and together we have developed a family of sophisticated automatic nuclear fuel inspection and characterisation systems. These systems are aimed at providing information on the behaviour of fuel components at their different stages of burning, as part of a material manufacturer research and optimisation programme.

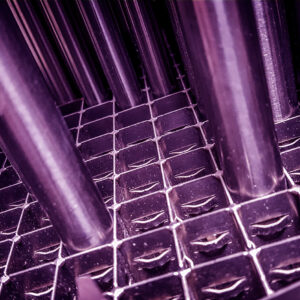

Among the other systems developed are inspection equipment for the measurement of oxide layers and the diameter of fuel cladding with micron precision, fuel component deformation measurement equipment for torsion, warping or tilting, detection and location systems for components with leaks and devices for the radiological characterisation of burnup fuel.

We have also developed automatic systems for the quality control of nuclear fuel during its manufacture stage. These systems permit the monitoring and control of a variety of critical fuel parameters such as enrichment, the composition of fuel pellets, rod enrichment areas, gadolinium content, spring position, rod surface defects, and others.

The execution of nuclear fuel inspection and characterisation services is carried out collectively by Tecnatom technicians who are experts in Non-Destructive Testing (NDT) and robotic equipment operation, and ENUSA technicians, who analyse and interpret the results of the inspection.

Our perfect symbiosis between an expert inspection technology company and a fuel manufacturing company allows us to develop high added-value automatic systems which are able to determine the critical parameters of nuclear fuel. The collective capacity of both companies delivers the optimum combination for the optimising of inspection system designs so as to obtain maximum nuclear fuel services, ensuring their operation with the utmost guarantee of reliability and safety.

This cooperation between Tecnatom and ENUSA goes back almost 30 years and we have provided inspection services and supplied automatic equipment to numerous customers all over the world.

The SICOM family of spent nuclear fuel inspection and characterisation equipment:

Quality control equipment for nuclear fuel production

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

NEXA™ Will Leverage Companies’ Expertise in Technology, Training and Operations Atlanta, Ga. – April 18, 2023 – Westinghouse Electric Company, Tecnatom and Accelerant Solutions announced

El proyecto ITER es uno de los proyectos de inversión más grandes del mundo, en el que colaboran más de 35 países con el objetivo de demostrar la viabilidad de la fusión nuclear como fuente de energía inagotable. Para ello se está construyendo uno de los dispositivos de fusión por confinamiento magnético más grandes del mundo, en el que se probarán tecnologías, materiales y regímenes físicos integrados necesarios para la producción de electricidad basada en la fusión.

Tecnatom forma parte del proyecto aportando la creación de la plataforma de simulación de lo que será el simulador de la sala de control de ITER, la integración de modelos existentes desarrollados por distintos suministradores, la integración del sistema de control CODAC, el desarrollo de modelos adicionales, así como el mantenimiento y la formación en la plataforma.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!