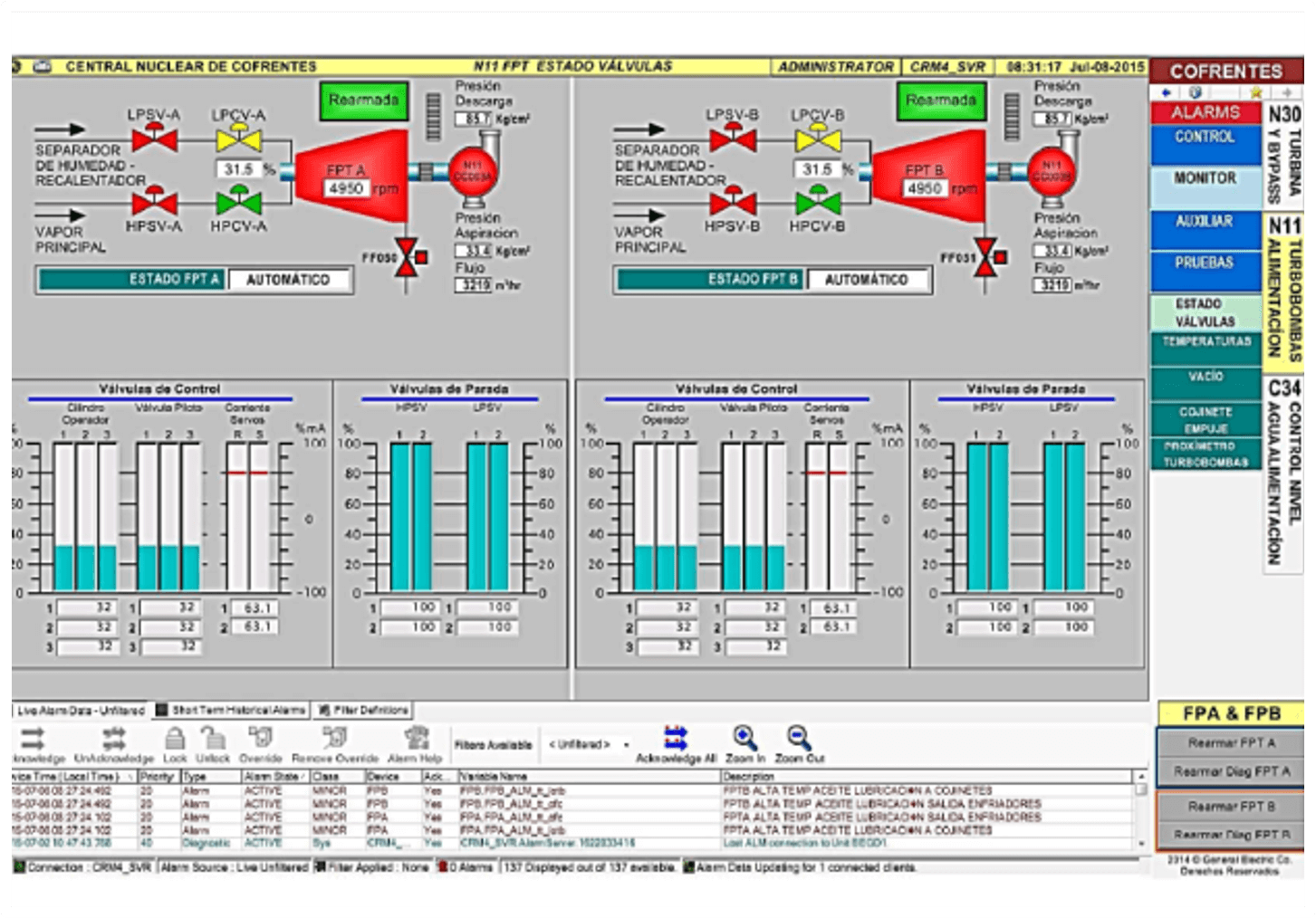

Tecnatom has extensive experience in the use of simulation for the optimization of the design and the implementation of plant modifications. As an example, in Cofrentes NPP, the SAE analysis in the replacement of the analog feedwater control system and turbopump control with a Mark Vie digital system, allowed the early detection of errors and the adjustment of parameters of the water loops control in the new system.

This resulted in an increase of efficiency and safety during commissioning.

Need more information? Download our brochure!

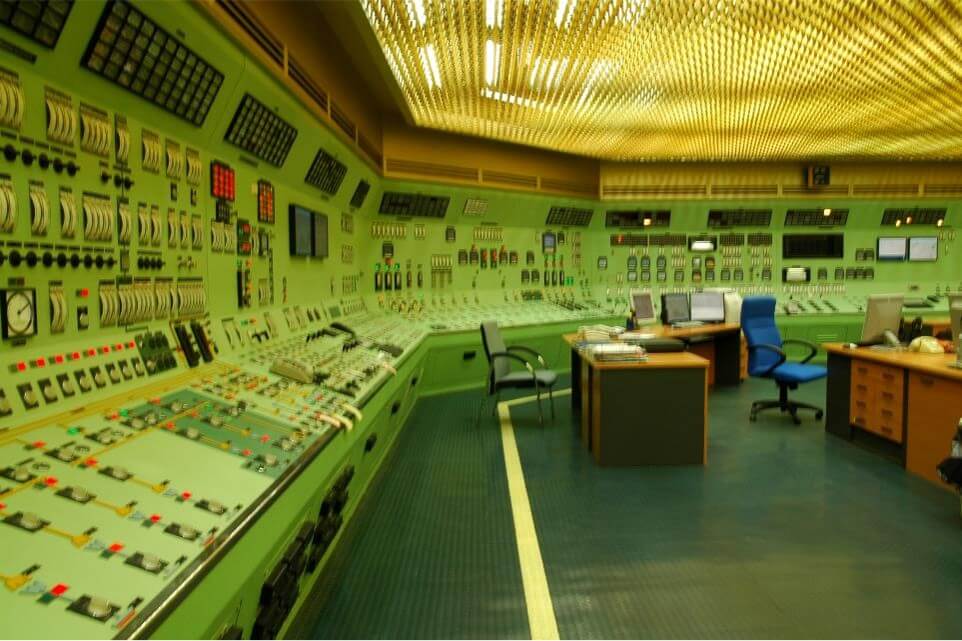

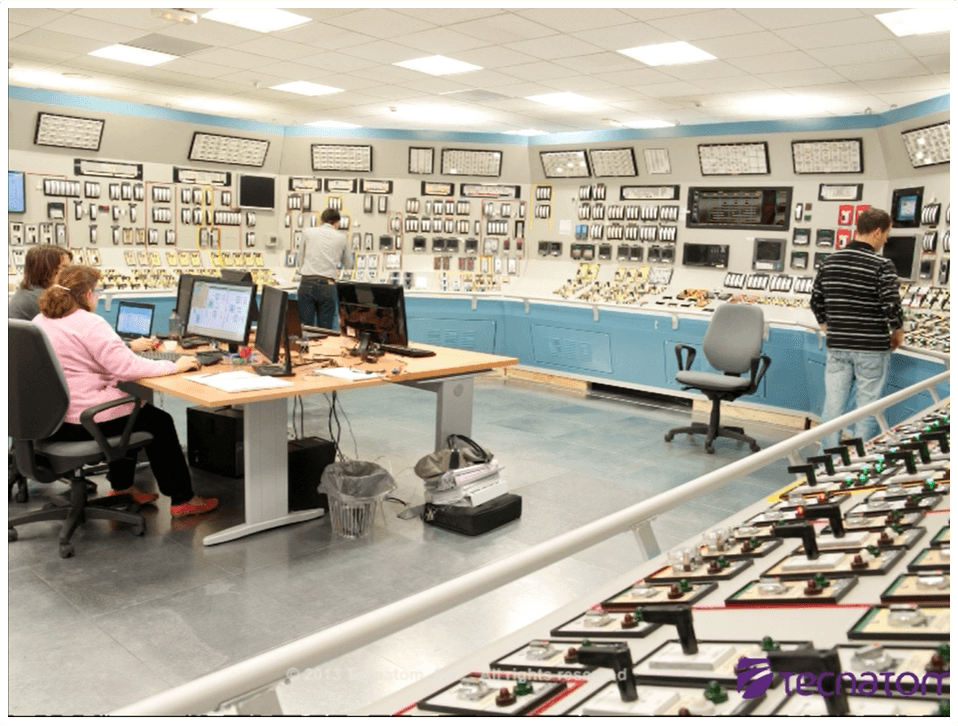

FSS simulate plant processes and recreate the main control room and the emergency control room at full-scale.These simulators are used in operator training, in licensing processes and as a tool to support plant engineering through simulation.

Tecnatom has designed, operates, and maintains all the SATs of the Spanish nuclear power plants.

Tecnatom has developed a full-scope simulator of its control room for the Atucha II Nuclear Power Plant.

this simulator is used for operator training and evaluation. In addition, the simulator was used to provide SAE support in the start-up of the installation.

Tecnatom has developed a full-scope simulator of the Angra I Nuclear Power Plant control room, located in Brazil.

This simulator is used for operator training and evaluation. In addition, Tecnatom performs simulation-assisted engineering (SAE) services in design modifications carried out at the facility.

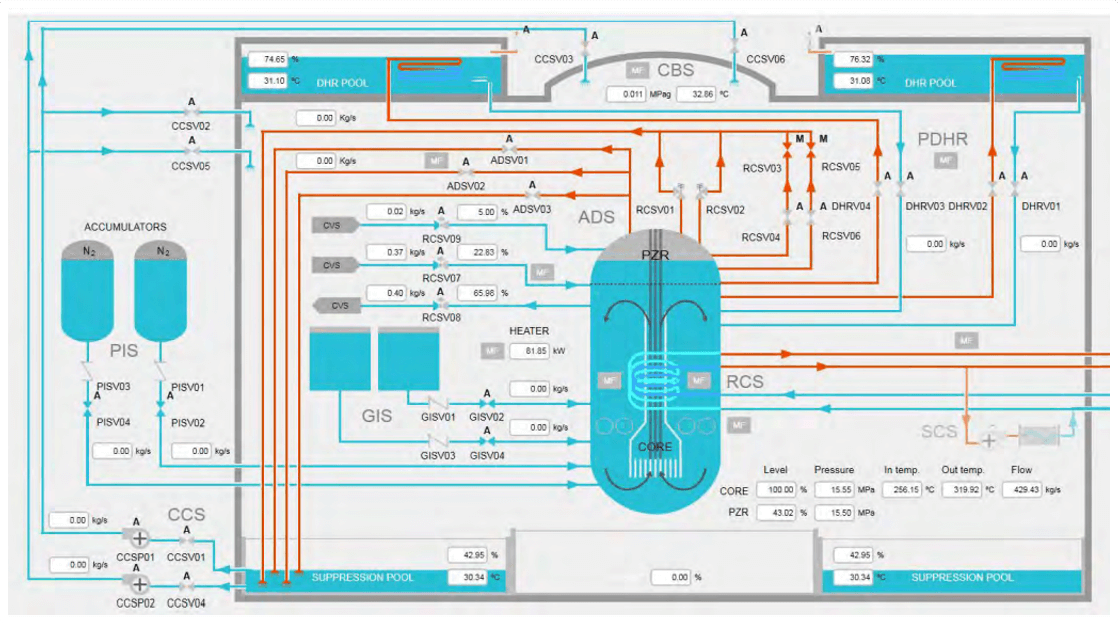

Tecnatom has supplied to the IAEA a basic principles simulator of a Small Modular Reactor (SMR) type iPWR, fully developed with our own technology.

This simulator is intended for the dissemination of the fundamentals of this technology to a non-specialized audience.

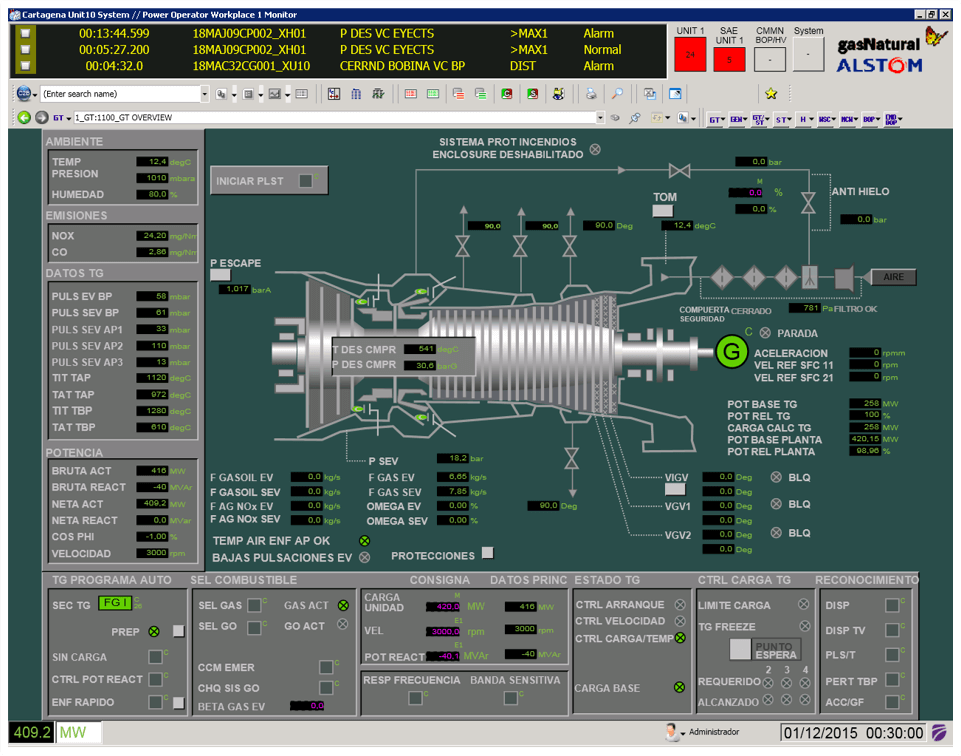

Tecnatom has developed, among other combined cycle simulators, a full-scope simulator of a plant with a GT26 turbine, which allows for the initial training of personnel, as well as the retraining of experienced operators. Some of the benefits of using the simulator are the increase in the availability of the plant, the improvement in performance and in the life of the components, the compliance with environmental regulations and the reduction of start-up times.

The isolated and autonomous systems have certain weaknesses caused by network instabilities and peaks in demand.

Tecnatom has developed for ENDESA a new and pioneering simulator for Los Guinchos diesel plant.

The simulator is used for training in blackout recovery scenarios, incident management and normal operation scenarios to optimize efficiency.

Thanks to its contribution to the availability of the plant, this simulator was the first out of eight others isolated system simulators.

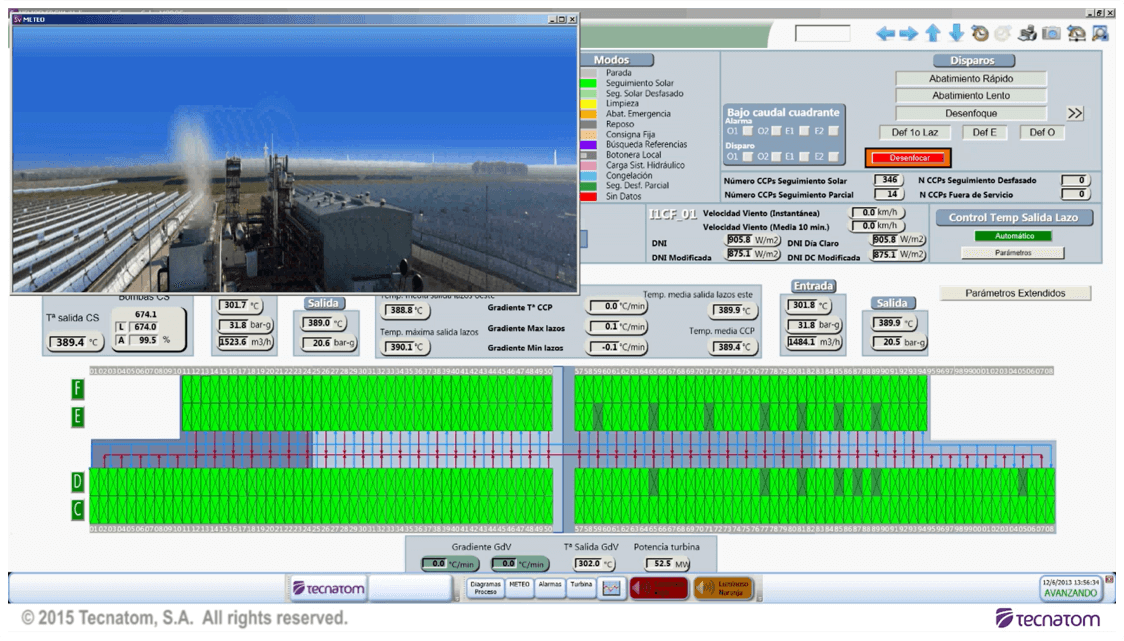

Tecnatom has developed a simulator for the KAXU SOLAR ONE parabolic cylinder CSP plant to be used throughout the entire life cycle of the installation.

During development, as an engineering tool as a commissioning support tool, to minimize unforeseen events as a training tool during exploitation.

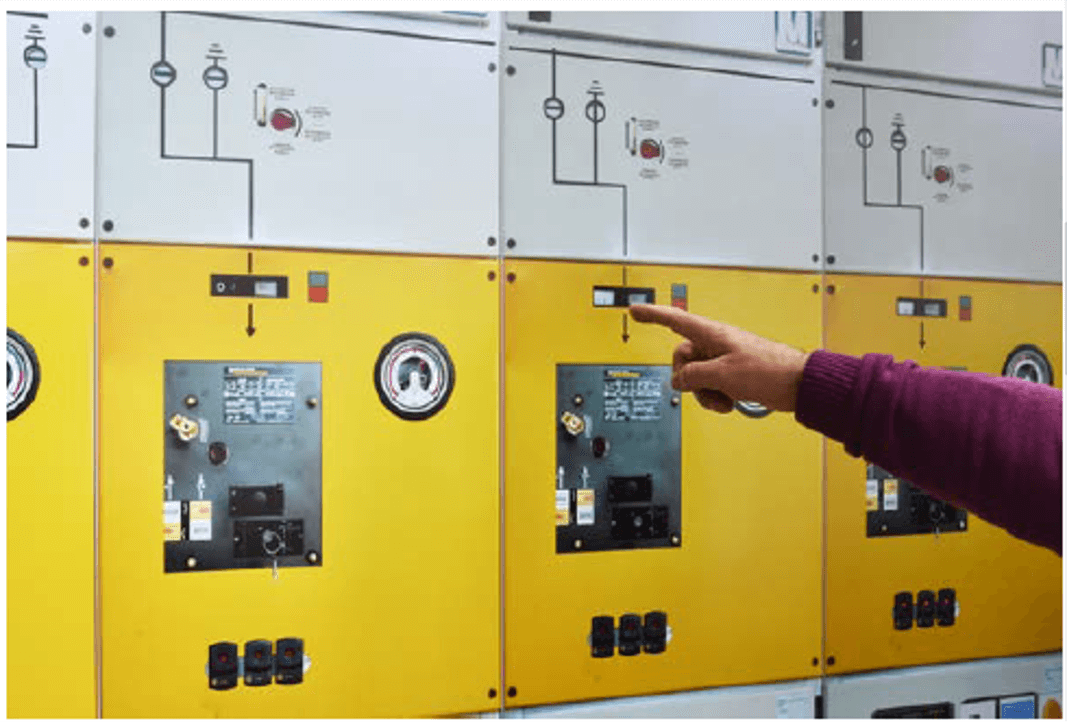

Maintaining the availability and safety in critical electrical installations is essential and very delicate, due to the complexity and infrequency of certain operations.

Tecnatom has developed and also carry out the maintenance for AENA electrical installations simulator where more than 500 operators have been trained.

El proyecto ITER es uno de los proyectos de inversión más grandes del mundo, en el que colaboran más de 35 países con el objetivo de demostrar la viabilidad de la fusión nuclear como fuente de energía inagotable. Para ello se está construyendo uno de los dispositivos de fusión por confinamiento magnético más grandes del mundo, en el que se probarán tecnologías, materiales y regímenes físicos integrados necesarios para la producción de electricidad basada en la fusión.

Tecnatom forma parte del proyecto aportando la creación de la plataforma de simulación de lo que será el simulador de la sala de control de ITER, la integración de modelos existentes desarrollados por distintos suministradores, la integración del sistema de control CODAC, el desarrollo de modelos adicionales, así como el mantenimiento y la formación en la plataforma.